- Home

- Steel Discs, Screws & Adhesives

Steel Discs, Screws & Adhesives

(42 Products)

- 1

- 2

Steel Discs, Screws & Adhesives

Explore Our Comprehensive Range of Steel Discs, Screws, and Adhesives

Steel discs, screws, and adhesives are essential components in the world of magnetism, offering robust solutions for a variety of applications. At FIRST4MAGNETS®, we provide a diverse selection of these products, meticulously designed to enhance the functionality of magnets in both industrial and personal projects.

Why Choose Steel Discs for Magnetic Applications?

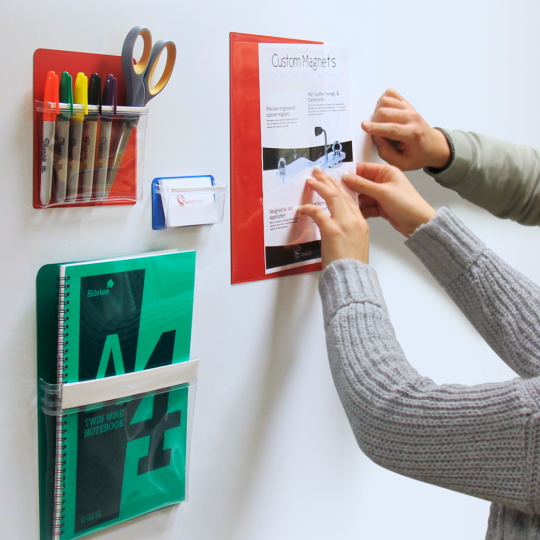

Steel discs serve as integral components in magnetic assemblies, offering a secure and reliable surface for magnets to adhere to. Available in multiple sizes, thicknesses, and finishes—such as nickel plating or painted coatings—these discs cater to a wide range of functional and aesthetic requirements. Whether you’re working on a simple display or a complex industrial task, our collection ensures there’s a steel disc that fits your specific needs.

Unmatched Strength and Versatility

Our steel discs provide unparalleled strength and versatility. Options range from 10mm diameter discs for precision tasks to larger 50mm diameter discs for heavy-duty applications. With typical thicknesses around 2mm, these discs deliver a solid foundation without adding unnecessary bulk, making them ideal for a wide array of uses.

Complementing our steel discs is a range of screws and adhesives carefully selected to provide the strength and support necessary for creating secure and durable magnetic assemblies. Whether for DIY projects, industrial applications, or crafting, these components ensure your magnetic solutions are efficient and long-lasting.

Features and Superior Quality Control

At FIRST4MAGNETS®, we prioritize the specific requirements of each project. Our steel discs are available with various features, including countersunk holes for screw fixing or 3M™ Self-Adhesive backing for easy application. Additionally, we offer finishes such as white and black paint to align with your design needs.

Every product undergoes rigorous quality testing to ensure it meets our high standards for performance and durability. From steel discs to screws and adhesives, our technical team provides expert guidance to help you select the perfect components for your application.

Diverse Applications of Steel Discs, Screws, and Adhesives

Our products are suitable for a wide range of applications, including:

- Magnetic catches

- Craft projects

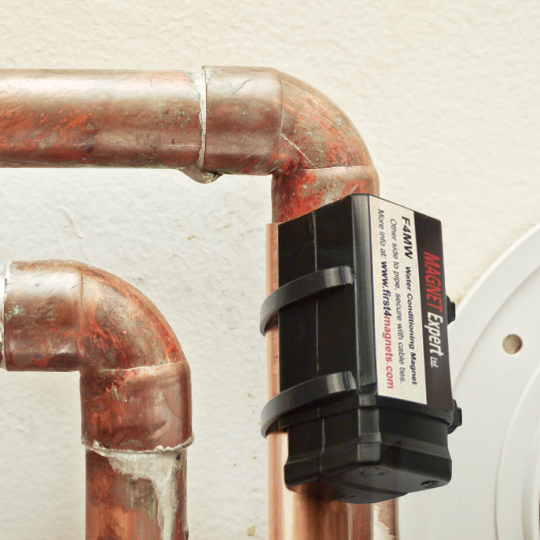

- Magnetic therapy devices

- Industrial and commercial assemblies

- DIY magnetic solutions

Their versatility makes them indispensable for both commercial and personal projects.

Why FIRST4MAGNETS® Is the Right Choice

When you choose FIRST4MAGNETS®, you’re selecting a trusted supplier that combines a wide range of high-quality products with exceptional customer service. Our extensive selection, expert advice, and customisation options ensure you’ll find the ideal solution for any magnetic need. For more information, explore our range or contact our expert team today.